A powerful, clean and quiet bulk liquid waste tanker.

We know how hard it is to find reliable information in the liquid waste industry! Check out our knowledge hub to keep you and your business on the cutting edge.

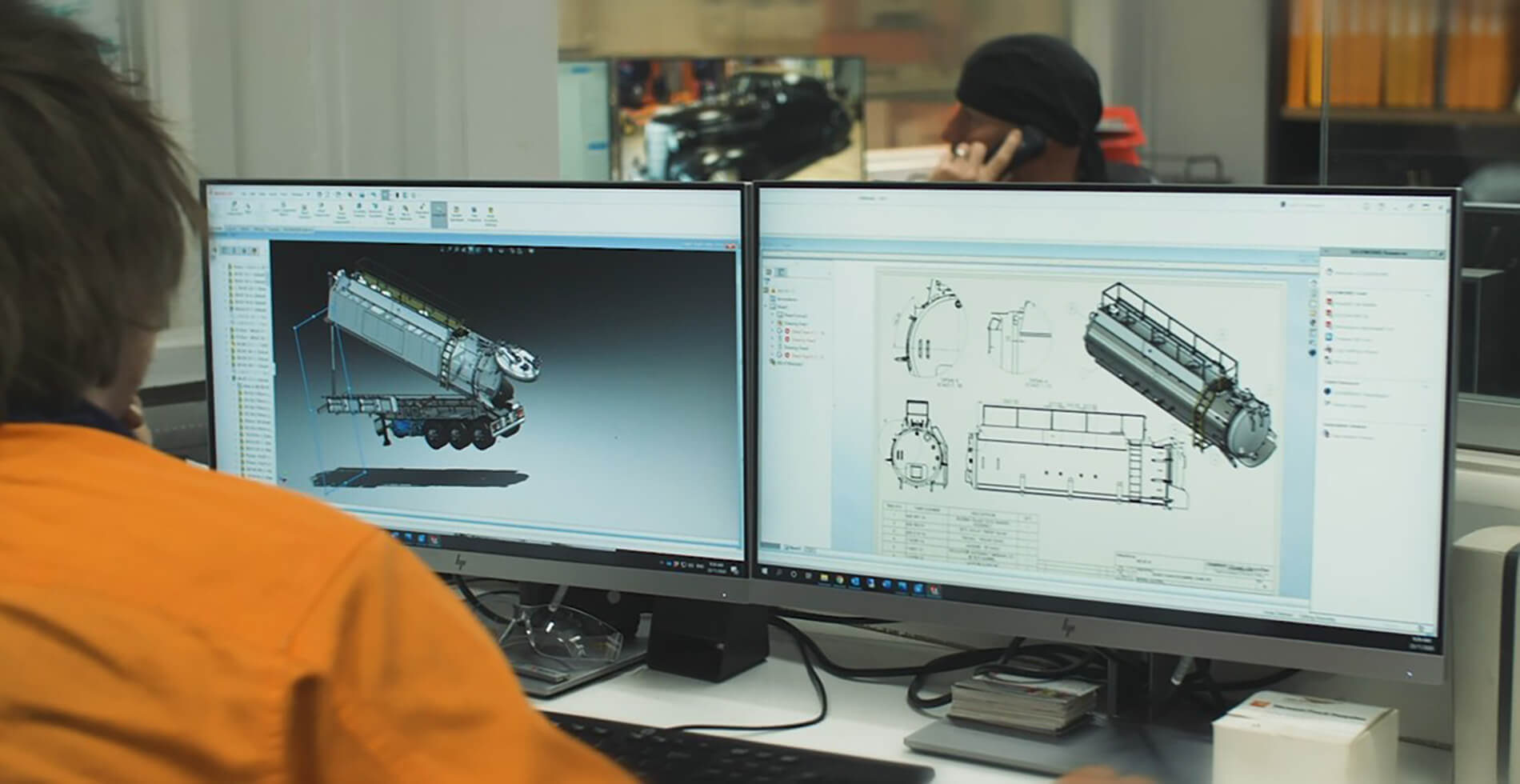

Whenever there is a need, we have a solution

Of course we are also capable of a diverse range of custom builds. If you have a need not addressed by our standardised range, please get in touch to discuss the details of your build.